I approach coding and labeling like a system, not a device. Get a clear plan, the right equipment, and the integration details that prevent downtime. With decades of experience across pharmaceutical, food & beverage, and automotive manufacturing, I bring a systems-first approach to industrial coding and labeling. My consulting services cover every phase—line assessment, solution design, equipment selection, software integration, and operator training—so you get more than a device. You get a reliable, compliant, future-ready identification system.

On-site or remote evaluation of your current line, data sources, substrates, speeds, and compliance needs.

Define the best approach for primary/secondary packaging identification, including fail-safes and reject logic.

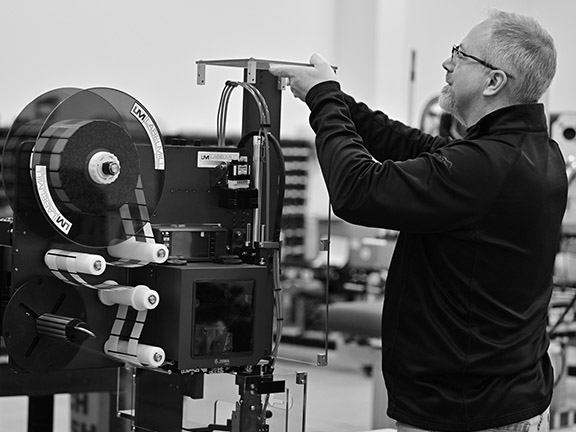

Shortlist printers, print-and-apply, scanners/vision, conveyors, and accessories aligned to your environment.

Connect variable data, ERP/WMS, barcode standards, and print validation—without breaking your workflow.

Hands-on training and documentation so your team can run, troubleshoot, and maintain the system confidently.

Optional 24/7 support model, spare parts planning, and continuous improvement based on downtime and defect data.

Every engagement begins with understanding your unique challenges. Whether you're planning a new line, troubleshooting an existing system, or navigating compliance requirements, let's talk about how a systems approach can transform your coding and labeling operations.