Every solution I deliver is built around the realities of your production environment—line speed, sanitation protocols, label adhesion, scan rates, and the relentless demand for consistent print quality. No theoretical fixes. No one-size-fits-all recommendations. Just practical, proven approaches to coding and labeling that hold up under real operating conditions.

Your product-level codes are the foundation of traceability—and the first line of defense in a recall. I design coding and marking strategies that deliver readable, durable, and consistent identification across substrates, whether you're printing on glass, plastic, film, or metal. From inkjet and laser to thermal transfer, the right technology depends on your line speed, environmental conditions, and regulatory requirements.

Case coding and carton labeling sit at the intersection of production and distribution. I help manufacturers implement solutions that meet retailer compliance requirements, maintain scanning reliability across the supply chain, and integrate cleanly with warehouse management systems. Whether it's high-resolution inkjet, label applicators, or direct thermal print, the goal is accuracy and uptime at every handoff.

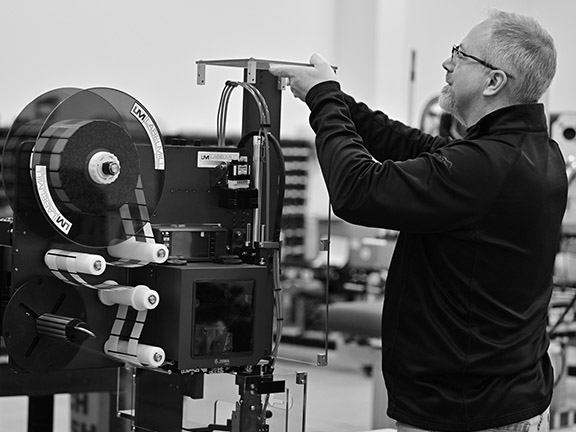

Manual labeling doesn't scale—and it introduces variability you can't afford. I specify and integrate print-and-apply systems tailored to your packaging geometry, line speed, and floor space constraints. That includes tamp, blow, and wipe applicators, dual-side labeling setups, and mounting solutions that fit your existing conveyors without major retrofits.

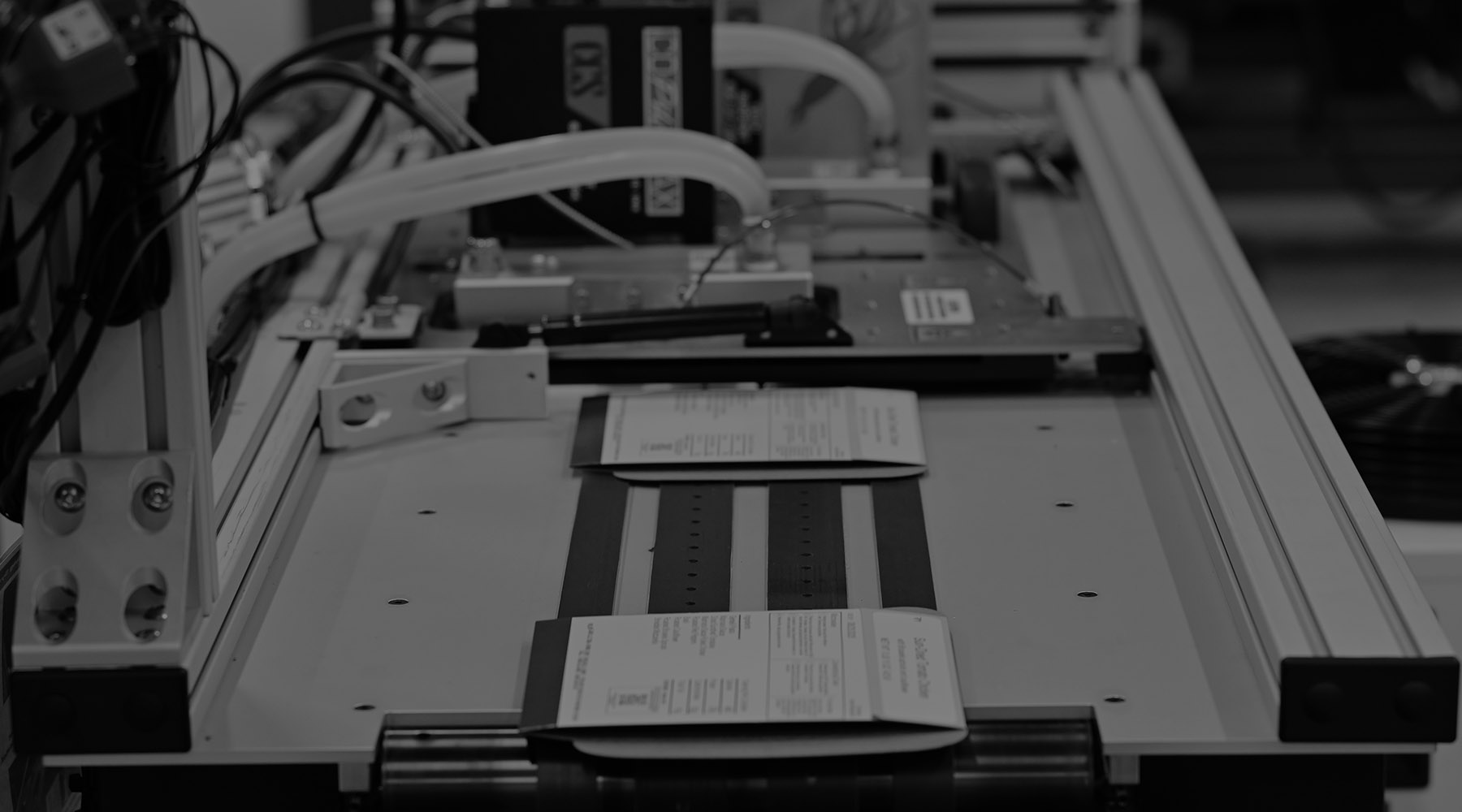

A printed code is only as good as its readability downstream. I implement barcode verification and vision inspection systems that catch mislabels, validate print quality against ISO grading standards, and trigger reject stations before bad product leaves the line. These systems close the loop between printing and quality assurance—reducing chargebacks, customer complaints, and recall exposure.

Coding and labeling don't exist in isolation—they're part of a broader packaging line. I help manufacturers think through the full end-of-line picture: conveyor layouts, case sealing, fume extraction for solvent-based inks, scanner placement, label rewinders, and palletizing considerations. The result is a cohesive system where every component works together, not against each other.

The wrong label stock can undermine even the best applicator. I advise on label materials, adhesive chemistry, and facestock selection for challenging environments—freezer storage, moisture exposure, chemical contact, and outdoor durability. For operations that also need large-format graphics, signage, or promotional materials, I help plan workflows that maintain brand consistency from product label to pallet wrap.

Every production environment is different. Line speeds vary. Substrates change. Compliance requirements evolve. Before recommending any solution, I take the time to understand your specific constraints—because a system that works flawlessly in one facility can fail completely in another. Let's talk about what you're trying to solve.